Fast Food Nation: What The All-American Meal is Doing to the World (22 page)

Read Fast Food Nation: What The All-American Meal is Doing to the World Online

Authors: Eric Schlosser

THE CHANGES THAT HAVE

swept through Greeley, Colorado, have also occurred throughout the High Plains, wherever large meatpacking plants operate. Towns like Garden City, Kansas, Grand Island, Nebraska, and Storm Lake, Iowa, now have their own rural ghettos, drugs, poverty, rootlessness, and crime. Some of the most dramatic changes have occurred in Lexington, Nebraska, a small town about

three hours west of Omaha. Lexington looks like the sort of place that Norman Rockwell liked to paint: shade trees, picket fences, modest Victorian homes, comfy chairs on front porches. The appearance is deceiving.

In 1990, IBP opened a slaughterhouse in Lexington. A year later, the town, with a population of roughly seven thousand, had the highest crime rate in the state of Nebraska. Within a decade, the number of serious crimes doubled; the number of Medicaid cases nearly doubled; Lexington became a major distribution center for illegal drugs; gang members appeared in town and committed drive-by shootings; the majority of Lexington’s white inhabitants moved elsewhere; and the proportion of Latino inhabitants increased more than tenfold, climbing to over 50 percent. “Mexington” — as it is now called, affectionately by some, disparagingly by others — is an entirely new kind of American town, one that has been transfigured to meet the needs of a modern slaughterhouse. You would never think, driving past the IBP plant in Lexington, with its colorful children’s playground out front, with Wal-Mart and Burger King across the street, that a single, innocuous-looking building could be responsible for so much sudden change, hardship, and despair.

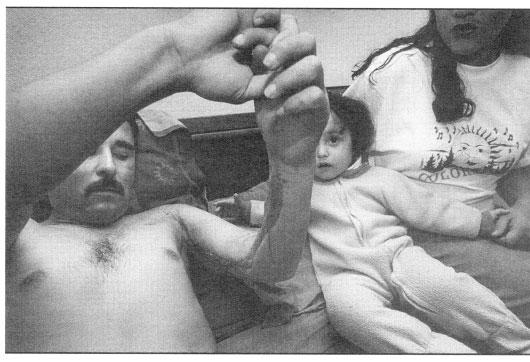

In Lexington I met a cross-section of IBP workers. I met Guatemalan Indians who spoke no English and barely spoke Spanish, living in a dark basement strewn with garbage and used diapers. I met Mexican farm workers struggling to get used to the long Nebraska winters. I met one IBP worker who’d recently been a housekeeper in Santa Monica and another whose previous job was collecting manure from fields in rural Mexico and selling it as fertilizer. I met hard-working, illiterate, religious people willing to risk injury and endure pain for the benefit of their families.

The smell that permeates Lexington is even worse than the smell of Greeley. “We have three odors,” a Lexington resident told a reporter: “burning hair and blood, that greasy smell, and the odor of rotten eggs.” Hydrogen sulfide is the gas responsible for the rotten egg smell. It rises from slaughterhouse wastewater lagoons, causes respiratory problems and headaches, and at high levels can cause permanent damage to the nervous system. In January of 2000, the Justice Department sued IBP for violations of the Clean Air Act at its Dakota City plant, where as much as a ton of hydrogen sulfide was being released into the air every day. As part of a consent decree, IBP agreed to cover its wastewater lagoons there. “This agreement means that Nebraskans

will no longer be forced to inhale IBP’s toxic emissions,” said a Justice Department official. As of this writing, IBP is also preparing to cover its Lexington wastewater lagoons.

On July 7,1988, IBP held a public forum at a junior high school in Lexington, giving local citizens an opportunity to ask questions about the company’s proposal to build a slaughterhouse there. The transcript of this meeting says a lot about how IBP views the rural communities where it operates. Would there be much turnover among workers at the new IBP plant, someone asked. Once the slaughterhouse was running, an IBP executive replied, it would have a stable workforce. “Ninety percent of our people,” he said, “or 80 percent will be fairly stable.” Would local people be hired for these jobs, someone else asked. “We will not bring in an hourly workforce,” the IBP executive promised. A local IBP booster, who had just returned from a visit to the company’s slaughterhouse in Emporia, Kansas, suggested there was little reason to worry about the “type of people” the plant might attract or the potential for increased crime. He said that in Emporia, apparently, “they work them so hard at IBP that they’re tired and they go home and go to bed.” An IBP executive, a vice president of public relations, confirmed that assessment. “And people who work on our lines work hard,” he told the gathering. “As the chief of police [in Emporia] said, they go home at night and go to bed rather than carouse around town.” Another IBP executive, a vice president of engineering, assured the audience that the new plant in Lexington would not foul the air. No odor would be noticeable, he promised, even “a few feet away” from the plant. In any event, the smell emitted by slaughterhouse lagoons would be “sweet,” not objectionable. And the smell from the slaughterhouse itself, the IBP vice president said, would be “no different than that which you produce in your kitchen when you cook.”

O

NE NIGHT I VISIT

a slaughterhouse somewhere in the High Plains. The slaughterhouse is one of the nation’s largest. About five thousand head of cattle enter it every day, single file, and leave in a different form. Someone who has access to the plant, who’s upset by its working conditions, offers to give me a tour. The slaughterhouse is an immense building, gray and square, about three stories high, with no windows on the front and no architectural clues to what’s happening inside. My friend gives me a chain-mail apron and gloves, suggesting I try them on. Workers on the line wear about eight pounds of chain mail beneath their white coats, shiny steel armor that covers their hands, wrists, stomach, and back. The chain mail’s designed to protect workers from cutting themselves and from being cut by other workers. But knives somehow manage to get past it. My host hands me some Wellingtons, the kind of knee-high rubber boots that English gentlemen wear in the countryside. “Tuck your pants into the boots,” he says. “We’ll be walking through some blood.”

I put on a hardhat and climb a stairway. The sounds get louder, factory sounds, the noise of power tools and machinery, bursts of compressed air. We start at the end of the line, the fabricating room. Workers call it “fab.” When we step inside, fab seems familiar: steel catwalks, pipes along the walls, a vast room, a maze of conveyer belts. This could be the Lamb Weston plant in Idaho, except hunks of red meat ride the belts instead of french fries. Some machines assemble cardboard boxes, others vacuum-seal subprimals of beef in clear plastic. The workers look extremely busy, but there’s nothing unsettling about this part of the plant. You see meat like this all the time in the back of your local supermarket.

The fab room is cooled to about 40 degrees, and as you head up the line, the feel of the place starts to change. The pieces of meat get bigger. Workers — about half of them women, almost all of them young and Latino — slice meat with long slender knives. They stand at a table that’s chest high, grab meat off a conveyer belt, trim away fat, throw meat back on the belt, toss the scraps onto a conveyer belt above them, and then grab more meat, all in a matter of seconds. I’m now struck by how many workers there are, hundreds of them, pressed close together, constantly moving, slicing. You see hardhats, white coats, flashes of steel. Nobody is smiling or chatting, they’re too busy, anxiously trying not to fall behind. An old man walks past me, pushing a blue plastic barrel filled with scraps. A few workers carve the meat with Whizzards, small electric knives that have spinning round blades. The Whizzards look like the Norelco razors that Santa rides in the TV ads. I notice that a few of the women near me are sweating, even though the place is freezing cold.

Sides of beef suspended from an overhead trolley swing toward a group of men. Each worker has a large knife in one hand and a steel hook in the other. They grab the meat with their hooks and attack it fiercely with their knives. As they hack away, using all their strength, grunting, the place suddenly feels different, primordial. The machinery seems beside the point, and what’s going on before me has been going on for thousands of years — the meat, the hook, the knife, men straining to cut more meat.

On the kill floor, what I see no longer unfolds in a logical manner. It’s one strange image after another. A worker with a power saw slices cattle into halves as though they were two-by-fours, and then the halves swing by me into the cooler. It feels like a slaughterhouse now. Dozens of cattle, stripped of their skins, dangle on chains from their hind legs. My host stops and asks how I feel, if I want to go any further. This is where some people get sick. I feel fine, determined to see the whole process, the world that’s been deliberately hidden. The kill floor is hot and humid. It stinks of manure. Cattle have a body temperature of about 101 degrees, and there are a lot of them in the room. Carcasses swing so fast along the rail that you have to keep an eye on them constantly, dodge them, watch your step, or one will slam you and throw you onto the bloody concrete floor. It happens to workers all the time.

I see: a man reach inside cattle and pull out their kidneys with his bare hands, then drop the kidneys down a metal chute, over and over again, as each animal passes by him; a stainless steel rack of tongues; Whizzards peeling meat off decapitated heads, picking them almost as clean as the white skulls painted by Georgia O’Keeffe. We wade through blood that’s ankle deep and that pours down drains into huge vats below us. As we approach the start of the line, for the first time I hear the steady

pop, pop, pop

of live animals being stunned.

Now the cattle suspended above me look just like the cattle I’ve seen on ranches for years, but these ones are upside down swinging on hooks. For a moment, the sight seems unreal; there are so many of them, a herd of them, lifeless. And then I see a few hind legs still kicking, a final reflex action, and the reality comes hard and clear.

For eight and a half hours, a worker called a “sticker” does nothing but stand in a river of blood, being drenched in blood, slitting the neck of a steer every ten seconds or so, severing its carotid artery. He uses a long knife and must hit exactly the right spot to kill the animal humanely. He hits that spot again and again. We walk up a slippery metal stairway and reach a small platform, where the production line begins. A man turns and smiles at me. He wears safety goggles and a hardhat. His face is splattered with gray matter and blood. He is the “knocker,” the man who welcomes cattle to the building. Cattle walk down a narrow chute and pause in front of him, blocked by a gate, and then he shoots them in the head with a captive bolt stunner — a compressed-air gun attached to the ceiling by a long hose — which fires a steel bolt that knocks the cattle unconscious. The animals keep strolling up, oblivious to what comes next, and he stands over them and shoots. For eight and a half hours, he just shoots. As I stand there, he misses a few times and shoots the same animal twice. As soon as the steer falls, a worker grabs one of its hind legs, shackles it to a chain, and the chain lifts the huge animal into the air.

I watch the knocker knock cattle for a couple of minutes. The animals are powerful and imposing one moment and then gone in an instant, suspended from a rail, ready for carving. A steer slips from its chain, falls to the ground, and gets its head caught in one end of a conveyer belt. The production line stops as workers struggle to free the steer, stunned but alive, from the machinery. I’ve seen enough.

I step out of the building into the cool night air and follow the path that leads cattle into the slaughterhouse. They pass me, driven toward the building by workers with long white sticks that seem to glow in the dark. One steer, perhaps sensing instinctively what the other don’t,

turns and tries to run. But workers drive him back to join the rest. The cattle lazily walk single-file toward the muffled sounds,

pop, pop, pop

, coming from the open door.

The path has hairpin turns that prevent cattle from seeing what’s in store and keep them relaxed. As the ramp gently slopes upward, the animals may think they’re headed for another truck, another road trip — and they are, in unexpected ways. The ramp widens as it reaches ground level and then leads to a large cattle pen with wooden fences, a corral that belongs in a meadow, not here. As I walk along the fence, a group of cattle approach me, looking me straight in the eye, like dogs hoping for a treat, and follow me out of some mysterious impulse. I stop and try to absorb the whole scene: the cool breeze, the cattle and their gentle lowing, a cloudless sky, steam rising from the plant in the moonlight. And then I notice that the building does have one window, a small square of light on the second floor. It offers a glimpse of what’s hidden behind this huge blank façade. Through the little window you can see bright red carcasses on hooks, going round and round.

KNOCKER

,

STICKER

,

SHACKLER

,

RUMPER

, First Legger, Knuckle Dropper, Navel Boner, Splitter Top/Bottom Butt, Feed Kill Chain — the names of job assignments at a modern slaughterhouse convey some of the brutality inherent in the work. Meatpacking is now the most dangerous job in the United States. The injury rate in a slaughterhouse is about three times higher than the rate in a typical American factory. Every year more than one-quarter of the meatpacking workers in this country — roughly forty thousand men and women — suffer an injury or a work-related illness that requires medical attention beyond first aid. There is strong evidence that these numbers, compiled by the Bureau of Labor Statistics, understate the number of meatpacking injuries that occur. Thousands of additional injuries and illnesses most likely go unrecorded.

Despite the use of conveyer belts, forklifts, dehiding machines, and a variety of power tools, most of the work in the nation’s slaughterhouses is still performed by hand. Poultry plants can be largely mechanized, thanks to the breeding of chickens that are uniform in size. The birds in some Tyson factories are killed, plucked, gutted, beheaded, and sliced into cutlets by robots and machines. But cattle

still come in all sizes and shapes, varying in weight by hundreds of pounds. The lack of a standardized steer has hindered the mechanization of beef plants. In one crucial respect meatpacking work has changed little in the past hundred years. At the dawn of the twenty-first century, amid an era of extraordinary technological advance, the most important tool in a modern slaughterhouse is a sharp knife.

Lacerations are the most common injuries suffered by meatpackers, who often stab themselves or stab someone working nearby. Tendinitis and cumulative trauma disorders are also quite common. Meatpacking workers routinely develop back problems, shoulder problems, carpal tunnel syndrome, and “trigger finger” (a syndrome in which a finger becomes frozen in a curled position). Indeed, the rate of these cumulative trauma injuries in the meatpacking industry is far higher than the rate in any other American industry. It is roughly thirty-three times higher than the national average in industry. Many slaughterhouse workers make a knife cut every two or three seconds, which adds up to about 10,000 cuts during an eight-hour shift. If the knife has become dull, additional pressure is placed on the worker’s tendons, joints, and nerves. A dull knife can cause pain to extend from the cutting hand all the way down the spine.

Workers often bring their knives home and spend at least forty minutes a day keeping the edges smooth, sharp, and sanded, with no pits. One IBP worker, a small Guatemalan woman with graying hair, spoke with me in the cramped kitchen of her mobile home. As a pot of beans cooked on the stove, she sat in a wooden chair, gently rocking, telling the story of her life, of her journey north in search of work, the whole time sharpening big knives in her lap as though she were knitting a sweater.

The “IBP revolution” has been directly responsible for many of the hazards that meatpacking workers now face. One of the leading determinants of the injury rate at a slaughterhouse today is the speed of the disassembly line. The faster it runs, the more likely that workers will get hurt. The old meatpacking plants in Chicago slaughtered about 50 cattle an hour. Twenty years ago, new plants in the High Plains slaughtered about 175 cattle an hour. Today some plants slaughter up to 400 cattle an hour — about half a dozen animals every minute, sent down a single production line, carved by workers desperate not to fall be-hind. While trying to keep up with the flow of meat, workers often neglect to resharpen their knives and thereby place more stress on their bodies. As the pace increases, so does the risk of accidental cuts and

stabbings. “I could always tell the line speed,” a former Monfort nurse told me, “by the number of people with lacerations coming into my office.” People usually cut themselves; nevertheless, everyone on the line tries to stay alert. Meatpackers often work within inches of each other, wielding large knives. A simple mistake can cause a serious injury. A former IBP worker told me about boning knives suddenly flying out of hands and ricocheting off of machinery. “They’re very flexible,” she said, “and they’ll spring on you… zwing, and they’re gone.”

Much like french fry factories, beef slaughterhouses often operate at profit margins as low as a few pennies a pound. The three meatpacking giants — ConAgra, IBP, and Excel — try to increase their earnings by maximizing the volume of production at each plant. Once a slaughterhouse is up and running, fully staffed, the profits it will earn are directly related to the speed of the line. A faster pace means higher profits. Market pressures now exert a perverse influence on the management of beef plants: the same factors that make these slaughterhouses relatively inefficient (the lack of mechanization, the reliance on human labor) encourage companies to make them even more dangerous (by speeding up the pace).

The unrelenting pressure of trying to keep up with the line has encouraged widespread methamphetamine use among meatpackers. Workers taking “crank” feel charged and self-confident, ready for anything. Supervisors have been known to sell crank to their workers or to supply it free in return for certain favors, such as working a second shift. Workers who use methamphetamine may feel energized and invincible, but are actually putting themselves at much greater risk of having an accident. For obvious reasons, a modern slaughterhouse is not a safe place to be high.

In the days when labor unions were strong, workers could complain about excessive line speeds and injury rates without fear of getting fired. Today only one-third of IBP’s workers belong to a union. Most of the nonunion workers are recent immigrants; many are illegals; and they are generally employed “at will.” That means they can be fired without warning, for just about any reason. Such an arrangement does not encourage them to lodge complaints. Workers who have traveled a great distance for this job, who have families to support, who are earning ten times more an hour in a meatpacking plant than they could possibly earn back home, are wary about speaking out and losing everything. The line speeds and labor costs at IBP’s nonunion plants now set the standard for the rest of the industry. Every other company

must try to produce beef as quickly and cheaply as IBP does; slowing the pace to protect workers can lead to a competitive disadvantage.

Again and again workers told me that they are under tremendous pressure not to report injuries. The annual bonuses of plant foremen and supervisors are often based in part on the injury rate of their workers. Instead of creating a safer workplace, these bonus schemes encourage slaughterhouse managers to make sure that accidents and injuries go unreported. Missing fingers, broken bones, deep lacerations, and amputated limbs are difficult to conceal from authorities. But the dramatic and catastrophic injuries in a slaughterhouse are greatly outnumbered by less visible, though no less debilitating, ailments: torn muscles, slipped disks, pinched nerves.

If a worker agrees not to report an injury, a supervisor will usually shift him or her to an easier job for a while, providing some time to heal. If the injury seems more serious, a Mexican worker is often given the opportunity to return home for a while, to recuperate there, then come back to his or her slaughterhouse job in the United States. Workers who abide by these unwritten rules are treated respectfully; those who disobey are likely to be punished and made an example. As one former IBP worker explained, “They’re trying to deter you, period, from going to the doctor.”

From a purely economic point of view, injured workers are a drag on profits. They are less productive. Getting rid of them makes a good deal of financial sense, especially when new workers are readily available and inexpensive to train. Injured workers are often given some of the most unpleasant tasks in the slaughterhouse. Their hourly wages are cut. And through a wide variety of unsubtle means they are encouraged to quit.

Not all supervisors in a slaughterhouse behave like Simon Legree, shouting at workers, cursing them, belittling their injuries, always pushing them to move faster. But enough supervisors act that way to warrant the comparison. Production supervisors tend to be men in their late twenties and early thirties. Most are Anglos and don’t speak Spanish, although more and more Latinos are being promoted to the job. They earn about $30,000 a year, plus bonuses and benefits. In many rural communities, being a supervisor at a meatpacking plant is one of the best jobs in town. It comes with a fair amount of pressure: a supervisor must meet production goals, keep the number of recorded injuries low, and most importantly, keep the meat flowing down the line without interruption. The job also brings enormous power. Each

supervisor is like a little dictator in his or her section of the plant, largely free to boss, fire, berate, or reassign workers. That sort of power can lead to all sorts of abuses, especially when the hourly workers being supervised are women.

Many women told me stories about being fondled and grabbed on the production line, and the behavior of supervisors sets the tone for the other male workers. In February of 1999, a federal jury in Des Moines awarded $2.4 million to a female employee at an IBP slaughterhouse. According to the woman’s testimony, coworkers had “screamed obscenities and rubbed their bodies against hers while supervisors laughed.” Seven months later, Monfort agreed to settle a lawsuit filed by the U.S. Equal Employment Opportunity Commission on behalf of fourteen female workers in Texas. As part of the settlement, the company paid the women $900,000 and vowed to establish formal procedures for handling sexual harassment complaints. In their lawsuit the women alleged that supervisors at a Monfort plant in Cactus, Texas, pressured them for dates and sex, and that male coworkers groped them, kissed them, and used animal parts in a sexually explicit manner.

The sexual relationships between supervisors and “hourlies” are for the most part consensual. Many female workers optimistically regard sex with their supervisor as a way to gain a secure place in American society, a green card, a husband — or at the very least a transfer to an easier job at the plant. Some supervisors become meatpacking Casanovas, engaging in multiple affairs. Sex, drugs, and slaughterhouses may seem an unlikely combination, but as one former Monfort employee told me: “Inside those walls is a different world that obeys different laws.” Late on the second shift, when it’s dark outside, assignations take place in locker rooms, staff rooms, and parked cars, even on the catwalk over the kill floor.