Bread Matters (3 page)

Authors: Andrew Whitley

How our bread has changed

The great achievement of modern industrial baking was to make a superficially attractive loaf using a high proportion of home-grown wheat. This provided a market for British cereal farmers and saved the bakers the tariffs on imported – mostly Canadian – flour. But to turn British wheat into the kind of bread that most people appeared to want, new methods were required:

- Wheat hybrids were bred to take advantage of intensive chemical agriculture and to produce flour that suited industrial baking methods.

- Millers separated the whole wheat more completely into its constituent parts, ground the flour finer and added enzymes to make it more consistent.

- To make the dough rise quickly, bakers massively increased the amount of yeast.

- Time was squeezed out of the baking process, and with it not just flavour but vital nutritional benefits.

- Freshness was redefined and artificially induced by means of additives, some undeclared.

A technological and commercial triumph turned out to be a nutritional own-goal.

Wheat

At the end of the Second World War, explosives manufacturers experienced a distinct decline in sales. If not exactly beating bombs into ploughshares, they found a ready outlet for their chemicals in the intensive agriculture that was seen as the only way to feed rapidly growing urban populations. Grain varieties were bred to respond to heavy applications of soluble nitrogen, potash and phosphorus fertilisers. But such a regime produces flabby straw that falls over in wind or rain. So wheats with short straw were developed.

Once hooked on soluble chemicals, the new varieties showed signs of succumbing more than before to fungal and pest attack. So new strains were bred for built-in resistance. Shorter stem length means less canopy to suppress weeds, meaning the new varieties also had to be able to thrive in the presence of herbicides. The millers wanted their say, too, so the breeding programme was tweaked to produce wheats with proteins more suitable for bread baking. And each year, yields had to go on rising.

Yield, short straw, disease resistance, milling quality – the plant breeders have obliged. They have done so, to date, without recourse to GM technology, though that is in the wings.

What is striking in all of this – for those of us who think that farming has something to do with feeding people to keep them in good health – is that nutritional quality doesn’t get a look in. No one seems to have asked whether, as variety succeeded variety with bewildering speed, wheat was getting better or worse to eat, more or less nutritious, more or less digestible. The most sophisticated science is used to analyse ‘quality’ differences between contenders for the UK National List of cereal varieties subject to Plant Breeders’ Rights. Yet, cereal scientists, along with the big millers and bakers, act as though, nutritionally, all wheat varieties are much the same. Advances in the purely functional properties of wheat have come at the price of reductions in its nutritional quality. The precursors of modern bread wheats – einkorn, emmer and spelt – all contain more nutrients than their commercial successors. Research at the International Maize and Wheat Improvement Center in Mexico revealed that the best traditional wheat varieties had about twice the iron and zinc of popular modern varieties, and their wild relatives had another half as much again

7

. In Europe, the French National Institute for Agricultural Research has shown that the mineral content of current French wheats is 30-40 per cent below that of older varieties

8

.

Milling methods

Before the invention of roller milling, all flour was produced by crushing wheat between revolving stones. All parts of the wheat – bran, germ and starchy endosperm – were pulverised and mixed together into what we know as wholemeal, or whole wheat, flour. If you wanted whiter flour, you had to sift the wholemeal through wire sieves or ‘bolting cloths’ made from cotton, linen or silk. The roller-milling system, deployed from 1870 onwards, was quite different. It passed the wheat between pairs of steel cylinders, which gradually stripped the layers off the grain, sifting the material thus produced into a series of streams, each containing a different fraction of the flour. These could be taken off and bagged separately or recombined to make ‘patent’ flours for various baking purposes.

Wholemeal flour is, in theory, the entire wheat grain (minus its husk) ground into flour. In British parlance, this is flour with a 100 per cent ‘extraction rate’: 100 per cent of the available flour or meal has been ‘extracted’ from the grain. White flour has only approximately 72 per cent of the content of the wheat, the remaining 28 per cent consisting of the bran layers on the outside of the grain and the germ tucked in one end. What used to be called ‘wheatmeal’ was about 85 per cent extraction. ‘Brown’ is a generic term describing flour of about 80 per cent extraction. Most of the vitamins and minerals are in the outer bran layers of wheat. In white flour milling, these are mostly sold for animal feed.

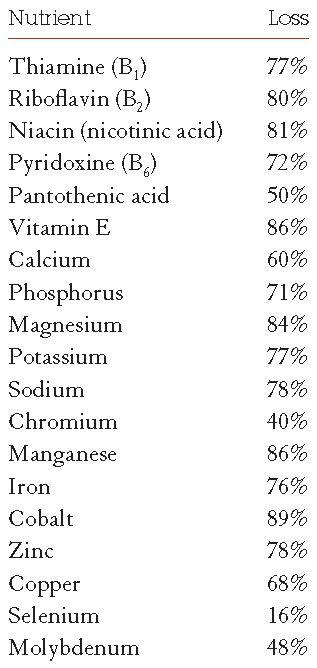

Wheat sold as breadmaking flour is more valuable in monetary terms to the miller than the residues that go to the animals. When it comes to nutritional value, however, the reverse is true. The table below shows what happens when whole wheat is milled to white flour

9

:

Vitamin and mineral loss during the refining of whole wheat to 70 per cent extraction white flour

The only word to describe bread made with such flour is ‘depleted’.

Whereas stone milling and sieving/bolting had generally produced a white flour consisting of 75-80 per cent of the original wheat, roller milling reduced this to 70-73 per cent. The visible effect was to produce a whiter flour with fewer flecks of bran in it. Far more important, however, was the reduction in the roller-milled flour of several important nutrients, including calcium, iron and B vitamins, which the stones had formerly dispersed throughout the flour. Removing the germ, which contains virtually all the valuable vitamin E of the wheat, was a nutritional disaster but a great benefit to the millers. The wheat germ oil tended to oxidise and go rancid within a few weeks. Without it, white flour could last for several months – exactly what was needed as milling companies became larger, with ever-longer distribution chains along the country’s fast-expanding network of railways and roads. Not for the last time, nutritional integrity was a casualty of the commercial need for ‘shelf life’. Some of the vitamin E, incidentally, goes to the supplement industry, which is happy to sell it back to us in capsules at many times what it might have cost us if we simply ate bread made with stoneground wholemeal flour.

In a French study in 2005, stoneground organic flour was shown to have 50 per cent more magnesium and 46 per cent more zinc than roller-milled non-organic flour

10

. This effect, it should be explained, was observed not in wholemeal but in flour milled to a finer extraction rate of around 80-85 per cent. Many people consume too little magnesium and the role of zinc in good health is well established. It would not be unreasonable to expect the benefits of organic growing (see page 43) and stone milling to apply similarly to other important micronutrients in flour.

The intriguing question is whether modern roller mills could be adapted to deliver flour with the same nutritional integrity as stoneground. It is hard to believe that the technological ingenuity would be lacking. But commercial will is quite another matter. The track record of the big milling concerns does not suggest a major commitment to the nutritional quality of their flour. Milling technology is currently focused on the functional effects to be had from producing ever finer fractions of flour.

In 1941 nutritional scientists persuaded the government to force a reluctant milling industry to add calcium to its white flour. Three other nutrients (iron, vitamin B

1

and nicotinic acid) were added in 1953 – although in lower amounts than would be found in wholemeal flour. All the other deficiencies and differences between stoneground and roller-milled and wholemeal and white flours listed above remain.

Official advice does now stress the importance of whole grain cereals in the diet. However, almost all the ‘whole’ wheat flour produced today is from roller mills. In other words, it is reassembled from the separated fractions of flour but without the crucial wheat germ oil, on the grounds that replacing it would shorten the flour’s shelf life. Perhaps such flour should be labelled ‘reconstituted semi-whole wheat flour’ to alert consumers to the fact that it does not contain all the elements of the original grain.

Yeast

Ever since our ancestors thousands of years ago noticed that a flour and water paste begins to aerate if left for some hours, people in wheat- and ryegrowing areas have eaten leavened bread. During fermentation, naturally occurring enzymes break carbohydrates down into sugars on which yeasts feed, producing carbon dioxide (the gas that raises the bread) and alcohol. This process was fully understood only after Louis Pasteur’s discovery in 1857 of the micro-organisms involved. It eventually became possible to identify and culture pure strains of yeast that gave fast and predictable results for breadmakers. Of the 160 or so known strains of yeast, the one commonly used for baker’s yeast is

Saccharomyces cerevisiae.

Other strains are involved in natural leavens and sourdoughs.

Before the development of commercial yeast in the late nineteenth century, bakers had to make their own, either with a ‘wild’ sourdough culture or by making a ‘barm’, which may have been seeded with yeast residue from a brewery. Either way, the process took time because the number of viable yeast cells in a sourdough or barm was relatively small. When commercial yeast became available, it contained much larger populations of cells and worked quickly. But it was expensive, and the thrifty baker could make it go further by using a small quantity in a preliminary ‘sponge’ consisting of a proportion of the flour and water to be used in the bread. This was allowed to ferment for 12 to 24 hours: given warmth, water and food, the yeast cells multiplied. On the following day, fresh flour and water (and occasionally some fat) would be added to make the final dough.

Even when commercial yeast became accessible to all bakers in the twentieth century, the ‘sponge-and-dough’ method remained a favoured way of breadmaking. In a typical overnight recipe from John Kirkland’s famous 1907 manual,

The Modern Baker, Confectioner and Caterer,

the yeast quantity is less than 0.1 per cent of the final dough weight. According to

The Master Bakers’ Book of Breadmaking

(National Association of Master Bakers, 1996), the Chorleywood Bread Process needs 2.38 per cent yeast for Vienna bread and rolls. In other words, over 23 times as much initial yeast as in Kirkland’s sponge-and-dough bread. Even compared with the fastest pre-War doughs, the Chorleywood Bread Process uses over three and a half times as much yeast.

If, after several decades in which most bread has been made with increased amounts of yeast, significant numbers of people develop an intolerance or allergy to yeast, it seems reasonable to ask whether there is a link. And there is another thing. Yeast, like the other raw materials of baking, has changed. It, too, needed a makeover if it was to be up to the task of Chorleywood baking. According to a manual for professional bakers,

Baking Problems Solved

(Stanley Cauvain and Linda Young, Woodhead Publishing Ltd, 2001):

‘When the CBP was introduced in the 1960s the type of baker’s yeast then used was unable to provide carbon dioxide gas in the critical early stages of baking and it became necessary for the yeast strain to be changed. Though the precise nature of the changes is not public knowledge it undoubtedly was related to the enzyme activity within the yeast cell.’ There’s an ominous note in that second sentence: the precise nature of the yeast used to make our national bread is ‘not public knowledge’. This was the 1960s – long (we thought) before the creeping capture of science by private business and certainly a good 20 years before the first emergence of genetic engineering.

About time, too

For almost all of mankind’s baking history, bread had taken a long time to rise. Bakers’ barms or sourdoughs contained relatively sparse populations of mixed strains of ‘wild’ yeasts. Whatever they were and wherever they came from, the one thing they had in common was that they worked slowly. The whole process from starter dough to finished product could take 24 hours or more. Single varieties of the most active strains of yeast appeared in the late nineteenth century and made faster fermentation possible. Though convenient, this was an expensive commercial option and most bakers eked out their yeast by using the sponge-and-dough method described above.