Fast Food Nation: What The All-American Meal is Doing to the World (15 page)

Read Fast Food Nation: What The All-American Meal is Doing to the World Online

Authors: Eric Schlosser

II / meat and potatoes

T

O REACH THE J

.

R

.

SIMPLOT PLANT

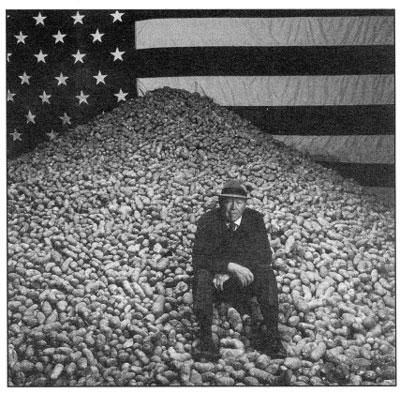

in Aberdeen, Idaho, you drive through downtown Aberdeen, population 2,000, and keep heading north, past the half dozen shops on Main Street. Then turn right at the Tiger Hut, an old hamburger stand named after a local high school team, cross the railroad tracks where freight cars are loaded with sugar beets, drive another quarter of a mile, and you’re there. It smells like someone’s cooking potatoes. The Simplot plant is low and square, clean and neat. The employee parking lot is filled with pickup trucks, and there’s a big American flag flying out front. Aberdeen sits in the heart of Bingham County, which grows more potatoes than any other county in Idaho. The Simplot plant runs twenty-four hours a day, three hundred and ten days a year, turning potatoes into french fries. It’s a small facility, by industry standards, built in the late 1950s. It processes about a million pounds of potatoes a day.

Inside the building, a maze of red conveyer belts crisscrosses in and out of machines that wash, sort, peel, slice, blanch, blow-dry, fry, and flash-freeze potatoes. Workers in white coats and hard hats keep everything running smoothly, monitoring the controls, checking the fries for imperfections. Streams of sliced potatoes pour from machines. The place has a cheerful, humble, Eisenhower-era feeling, as though someone’s dream of technological progress, of better living through frozen food, has been fulfilled. Looming over the whole enterprise is the spirit of one man: John Richard Simplot, America’s great potato baron, whose seemingly inexhaustible energy and willingness to take risks built an empire based on french fries. By far the most important figure in one of the nation’s most conservative states, Simplot displays the contradictory traits that have guided the economic

development of the American West, the odd mixture of rugged individualism and a dependence upon public land and resources. In a portrait that hangs above the reception desk at the Aberdeen plant, J. R. Simplot has the sly grin of a gambler who’s scored big.

Simplot was born in 1909. His family left Dubuque, Iowa, the following year and eventually settled in Idaho. The Snake River Reclamation Project was offering cheap water for irrigation, funded by the U.S. government, that would convert the desert of southern Idaho into lush farmland. Simplot’s father became a homesteader, obtaining land for free and clearing it with a steel rail dragged between two teams of horses. Simplot grew up working hard on the farm. He rebelled against his domineering father, dropped out of school at the age of fifteen, and left home. He found work at a potato warehouse in the small town of Declo, Idaho. He sorted potatoes with a “shaker sorter,” a hand-held device, nine to ten hours a day for 30 cents an hour. At the boarding house where he rented a room, Simplot met a group of schoolteachers who were being paid not in cash but in interest-bearing scrip. Simplot bought the scrip from the teachers for 50 cents on the dollar — and then sold the scrip to a local bank for 90 cents on the dollar. With his earnings, Simplot bought a rifle, an old truck, and 600 hogs for $1 a head. He built a cooker in the desert, stoked it with sagebrush, shot wild horses, skinned them, sold their hides for $2 each, cooked their meat, and fed the horse meat to his hogs through the winter. That spring, J. R. Simplot sold the hogs for $12.50 a head and, at the age of sixteen, became a potato farmer.

The Idaho potato industry was just getting started in the 1920s. The state’s altitude, warm days, cool nights, light volcanic soil, and abundance of irrigation water made it an ideal setting for growing Russet Burbank potatoes. Simplot leased 160 acres, then bought farm equipment and a team of horses. He learned how to grow potatoes from his landlord, Lindsay Maggart, who raised yields by planting fresh seed every year. In 1928, Simplot and Maggart purchased an electric potato sorter; it seemed a remarkable invention. Simplot began sorting potatoes for his friends and neighbors, but Maggart did not want to share the new device with anyone else. The two men fought over the potato sorter and then agreed to settle who owned it with the flip of a coin. J. R. Simplot won the coin toss, got the sorter, sold all his farm equipment, and started his own business in a potato cellar in Declo. He traveled the Idaho countryside, plugging the rudimentary machine into the nearest available light socket and sorting potatoes for farmers.

Soon he was buying and selling potatoes, opening warehouses, forming relationships with commodities brokers nationwide. When J. R. Simplot needed timber for a new warehouse, he and his men would just head down to Yellowstone and chop down some trees. Within a decade, Simplot was the largest shipper of potatoes in the West, operating thirty-three warehouses in Oregon and Idaho.

Simplot also shipped onions. In 1941, he started to wonder why the Burbank Corporation, an outfit in California, was ordering so many of his onions. Simplot went to California and followed one of the company’s trucks to a prune orchard in Vacaville, where the Burbank Corporation was using prune dryers to make dehydrated onions. Simplot immediately bought a six-tunnel prune dryer and set up his own dehydration plant in Caldwell, Idaho. The plant opened on October 8, 1941. Two months later, the United States entered World War II, and Simplot began selling dehydrated onions to the U.S. Army. It was a profitable arrangement. The dehydrated onion powder, he later recalled, was like “gold dust.”

The J. R. Simplot Dehydrating Company soon perfected a new method for drying potatoes and became one of the principal suppliers of food to the American military during World War II. In 1942, the company had a hundred workers at the Caldwell plant; by 1944, it had about twelve hundred. The Caldwell facility became the largest dehydrating plant in the world. J. R. Simplot used the profits earned as a military contractor to buy potato farms and cattle ranches, to build fertilizer plants and lumber mills, to stake mining claims and open a huge phosphate mine on the Fort Hall Indian Reservation. By the end of World War II, Simplot was growing his own potatoes, fertilizing them with his own phosphate, processing them at his factories, shipping them in boxes from his lumber yards, and feeding the leftover potato scraps to his cattle. He was thirty-six years old.

After the war, Simplot invested heavily in frozen food technology, betting that it would provide the meals of the future. Clarence Birds-eye had patented a number of techniques for flash-freezing in the 1920s. But sales of Birdseye’s new products were hampered, among other things, by the fact that few American grocery stores, and even fewer households, owned a freezer. The sales of refrigerators, freezers, and other kitchen appliances soared after World War II. The 1950s soon became “the Golden Age of Food Processing,” in the words of historian Harvey Levenstein, a decade in which one marvelous innovation after another promised to simplify the lives of American housewives:

frozen orange juice, frozen TV dinners, the Chicken-of-Tomorrow, “Potato salad from a package!”, Cheese Whiz, Jell-O salads, Jet-Puffed Marshmallows, Miracle Whip. Depression-era scarcity gave way to a cornucopia of new foods on the shelves of new suburban supermarkets. Ad campaigns made processed foods seem better than fresh ones, more space-age and up to date. According to Levenstein, many restaurants proudly displayed their canned soups, and a chain called Tad’s 30 Varieties of Meals featured frozen dinners on its menu. Customers at Tad’s cooked the frozen meals at tableside microwave ovens.

Postwar refrigerators came with freezer compartments, and J. R. Simplot thought about the foods that housewives might want to put in them. He assembled a team of chemists, led by Ray Dunlap, to develop a product that seemed to have enormous potential: the frozen french fry. Americans were eating more fries than ever before, and the Russet Burbank, with its large size and high starch content, was the perfect potato for frying. Simplot wanted to create an inexpensive frozen fry that tasted just as good as a fresh one. Although Thomas Jefferson had brought the Parisian recipe for

pommes frites

to the United States in 1802, french fries did not become well known in this country until the 1920s. Americans traditionally ate their potatoes boiled, mashed, or baked. French fries were popularized in the United States by World War I veterans who’d enjoyed them in Europe and by the drive-in restaurants that subsequently arose in the 1930s and 1940s. Fries could be served without a fork or a knife, and they were easy to eat behind the wheel. But they were extremely time-consuming to prepare. Simplot’s chemists experimented with various methods for the mass production of french fries, enduring a number of setbacks, learning the hard way that fries will sink to the bottom of a potato chip fryer and then burn. One day Dunlap walked into J. R. Simplot’s office with some frozen fries that had just been reheated. Simplot tasted them, realized the manufacturing problems had been solved, and said, “That’s a helluva thing.”

J. R. Simplot started selling frozen french fries in 1953. Sales were initially disappointing. Although the frozen fries were precooked and could be baked in an oven, they tasted best when heated in hot oil, limiting their appeal to busy homemakers. Simplot needed to find institutional customers, restaurant owners who’d recognize the tremendous labor-saving benefits of his frozen fries.

“The french fry [was]… almost sacrosanct for me,” Ray Kroc wrote

in his memoir, “its preparation a ritual to be followed religiously.” The success of Richard and Mac McDonald’s hamburger stand had been based as much on the quality of their fries as on the taste of their burgers. The McDonald brothers had devised an elaborate system for making crisp french fries, one that was later improved by the restaurant chain. McDonald’s cooked thinly sliced Russet Burbanks in special fryers to keep the oil temperature above 325 degrees. As the chain expanded, it became more difficult — and yet all the more important — to maintain the consistency and quality of the fries. J. R. Simplot met with Ray Kroc in 1965. The idea of switching to frozen french fries appealed to Kroc, as a means of ensuring uniformity and cutting labor costs. McDonald’s obtained its fresh potatoes from about 175 different local suppliers, and crew members spent a great deal of time peeling and slicing potatoes. Simplot offered to build a new factory solely for the manufacture of McDonald’s french fries. Kroc agreed to try Simplot’s fries, but made no long-term commitment. The deal was sealed with a handshake.

McDonald’s began to sell J. R. Simplot’s frozen french fries the following year. Customers didn’t notice any difference in taste. And the reduced cost of using a frozen product made french fries one of the most profitable items on the menu — far more profitable than hamburgers. Simplot quickly became the main supplier of french fries to McDonald’s. At the time, McDonald’s had about 725 restaurants in the United States. Within a decade, it had more than 3,000. Simplot sold his frozen fries to other restaurant chains, accelerating the growth of the fast food industry and changing the nation’s eating habits. Americans have long consumed more potatoes than any other food except dairy products and wheat flour. In 1960, the typical American ate eighty-one pounds of fresh potatoes and about four pounds of frozen french fries. Today the typical American eats about forty-nine pounds of fresh potatoes every year — and more than thirty pounds of frozen french fries. Ninety percent of those fries are purchased at fast food restaurants. Indeed, french fries have become the most widely sold foodservice item in the United States.

J. R. Simplot, an eighth-grade dropout, is now one of the richest men in the United States. His privately held company grows and processes corn, peas, broccoli, avocados, and carrots, as well as potatoes; feeds and processes cattle; manufactures and distributes fertilizer; mines phosphate and silica; produces oil, ethanol, and natural gas. In 1980, Simplot provided $1 million in start-up funds to a couple

of engineers working in the basement of a dentist’s office in Boise, Idaho. Twenty years later, his investment in Micron Technology — a manufacturer of computer memory chips and the largest private employer in Idaho — was worth about $1.5 billion. Simplot is also one of the nation’s biggest landowners. “I’ve been a land hog all my life,” Simplot told me, laughing. While still in his teens, he bought 18,000 acres along the Snake River, paying 50 cents an acre for it with borrowed money. His company now has 85,000 acres of irrigated farmland, and Simplot personally owns more than twice that amount of ranchland. He owns much of downtown Boise and a big hillside home overlooking the city. At home he flies a gigantic American flag on a pole that’s ten stories high. In addition to what he owns, Simplot leases more than 2 million acres of land from the federal government. His ZX Ranch in southern Oregon is the largest cattle ranch in the United States, measuring 65 miles wide and 163 miles long. Altogether, Simplot controls a bloc of North American land that’s bigger than the state of Delaware.