Make: Electronics (87 page)

Authors: Charles Platt

Experiment 35: Checking the Real World

Often we want a microcontroller to measure something and respond in an appropriate way. For instance, it can measure a low temperature and sound an alarm, as I suggested in the example that I gave earlier.

The PICAXE has three analog-to-digital converters (ADCs) built in, accessible via logic pins 1, 2, and 4, as shown in Figure 5-139. The best way to use them is by applying a potential somewhere between 0 and 5 volts. In this experiment, I’ll show you how to calibrate the response of the chip.

You will need:

- Trimmer potentiometer, 2K. Quantity: 1.

- PICAXE 08M chip and associated USB cable and socket. Quantity: 1 of each.

Procedure

Take the same trimmer potentiometer that you used in

Experiment 32

and wire its center terminal to Logic Pin 2 of the PICAXE (which is hardware pin 5). The other two terminals of the 2K trimmer go to positive and to negative, respectively. So depending how you set the trimmer, the pin of the PICAXE is directly connected to positive (at one end of the scale), or directly connected to negative (at the other end of the scale), or somewhere in between. See Figure 5-144 for the revised schematic, and Figure 5-145 for a photograph of the breadboarded circuit.

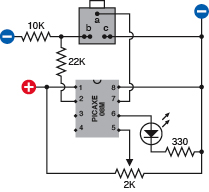

Figure 5-144.

This schematic, drawn in a layout suitable for breadboarding, shows how a 2K potentiometer can be used to apply a varying voltage to one of the pins of the PICAXE that is capable of converting an analog signal to a digital value.

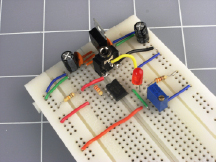

Figure 5-145.

The trimmer potentiometer added to the previously breadboarded circuit.

Now we need a program to tell the chip what to do. Using the Programming Editor, start a new document. The code should look like this:

main:

readadc 2,b0

debug b0

goto main

The command “readadc 2,b0” means “read the analog input on Logic Pin 2, convert from analog to digital, and store the result in b0.”

The command “debug b0” tells the chip to go into program debugging mode, in which it uses its USB cable to tell the Programming Editor the values of all the variables while the program is running. The variables are displayed in a debugging window.

Download the program, and as the program starts to execute, the debugging window should open. Start adjusting the trimmer while looking at the value of b0, and you’ll see b0 change its value.

You can make a table and draw a graph showing the relationship between the resistance between Logic Pin 2 and ground, and the value of b0. Just pull the trimmer off the breadboard, measure its resistance with a meter, then increase its resistance by, say, 200Ω, put it back into the breadboard, and look at the value of b0 again.

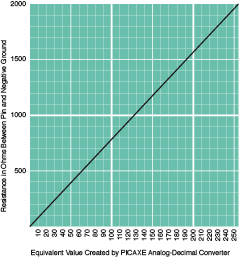

This is laborious, but calibrating equipment is always laborious—and in any case, I decided to do it for you. The graph is shown in Figure 5-146. You can also see the raw data numbers in the following table. I was pleased to find that the PICAXE gives a very precise, linear response to the input voltage. In other words, the graph is a straight line.

Figure 5-146.

When an ADC input pin is hooked up to a 2K potentiometer, which is connected across the same voltage that powers the chip, you should find that the resistance between the input pin and the negative side of the power supply generates the series of digital values shown on the graph. Note that the potentiometer must have a 2K value, and the power supply is assumed to be precisely 5 volts.

This table shows measurements made with PICAXE 08M controller.

Resistance (in ohms) between the ADC pin and the negative supply | Equivalent digital value |

2000 | 255 |

1900 | 243 |

1800 | 230 |

1700 | 218 |

1600 | 205 |

1500 | 192 |

1400 | 179 |

1300 | 166 |

1200 | 154 |

1100 | 141 |

1000 | 128 |

900 | 115 |

800 | 102 |

700 | 90 |

600 | 77 |

500 | 64 |

400 | 51 |

300 | 38 |

200 | 26 |

100 | 13 |

0 | 0 |

Now we can modify the program to make it do something with the information that it’s taking in:

main:

readadc 2,b0

let w1 = 5 * b0

high 1

pause w1

low 1

pause w1

goto main

Notice what’s happening here. First we get a value in b0, and then on the next line, we do some arithmetic with it. The asterisk means “multiply.” So the statement says, “Take whatever value is in b0, multiply by 5, and transfer it to another variable, w1.” We have to use a w variable, because when we multiply the value of b0 by 5, we may get a number that is bigger than 255—too big to fit into a byte variable.

Finally, we take variable w1 and use it with a “pause” statement instead of a fixed number value. We’re saying to the PICAXE, “pause for whatever number of microseconds you get by checking the value of w1.”

So the software checks a variable resistance, turns it into a number, and applies that number to adjust the flashing speed of the LED.

Think back to the need of the cart powered by stepper motors. It was supposed to check two photoresistors, and adjust the speed of each motor accordingly. Well, this PICAXE program is a step in that direction. It can measure voltage on a pin and change the output frequency on another pin. If you had two PICAXE chips, you could wire each of them to a photoresistor and a motor. Then you could adjust the behavior of your cart by editing the second line in the program, where it converts the value of b0 to the value of w1 which will be used in the “pause” command to determine the number of pulses per second. Instead of multiplying by 5 you could multiply by 7 or whatever number gives you the result you need. This leads to an important conclusion:

a big advantage of a programmable chip is that you can make adjustments in software

.

Because the PICAXE 08M actually has more than one ADC input, and has three pins that can be used for output, you might wonder whether you could use just the one chip to control both motors in response to inputs from two sensors. The problem is that the three output pins on the 08M also function as the three ADC input pins. You’d do better to buy one of the more advanced PICAXE chips, such as the 18M, which has more pins to choose from. It uses the same basic set of programming instructions, and doesn’t cost much more money.

Also, you should read the PICAXE documentation and look up the “pwmout” command, which is short for “pulse-width modulation output,” but you can think of as meaning “power motor output.” This is specifically intended to run stepper motors. It establishes an output frequency of pulses that will continue while the chip obeys other instructions in its program.

Fundamentals

Extra features

A complete guide to the 08M would fill a book of its own, and of course such books already exist (just search the books section of Amazon.com for keyword “picaxe”). But I’ll finish my introduction to the controller by listing some of its extra capabilities, leaving you to look them up and explore them. Then I’m going to suggest one last experiment.

Interrupts

The PICAXE 08M allows you to set one “interrupt.” This feature tells the chip to make a mental note that if a particular event occurs—such as a switch applying voltage to one pin—it should stop doing whatever else it was doing, and respond to the interruption.

Infrared

One pin on the PICAXE 08M can be used to receive infrared signals from a TV-style remote that you can buy from the same suppliers that sell the PICAXE itself. With an infrared sensor attached to the chip, you can issue commands remotely. If you want to build a remote-controlled robot, the chip is specifically designed with this in mind.

Servo motors

Every PICAXE chip has at least one pin that can send a stream of pulses to control a typical servo motor. On the 08M chip, it’s Logic Pin 2. The width of each pulse tells the motor how far to rotate from its center position before stopping. A 555 timer can send this stream, but the PICAXE makes it easier. You can search online for more information about servo motors, which are especially useful for applications such as steering model vehicles, adjusting the flaps on model airplanes, and actuating robots.

Music

The PICAXE has an onboard tone generator that can be programmed with a “tune” command to play tunes that you write using a simple code.

Alphanumeric input/output

The “kbin” programming command is available in the PICAXE models 20X2, 28X1 and 28X2, and 40X1 and 40X2. You can plug a standard computer keyboard into the chip, and it will read the keypresses. You can also attach alphanumeric displays, but these procedures are nontrivial. For instance, when you’re trying to figure out which key someone has pressed on a keyboard, your program has to contain a list of the special hexadecimal codes that the keyboard creates.

Pseudorandom number generation

All PICAXE models can generate pseudorandom numbers using a built-in algorithm. If you initialize the number generator by asking the user to press a button, and you measure the arbitrary time that this takes, you can seed the pseudorandom number generator with the result, and the pseudorandom number generator will have a less repeatable sequence.

Visit

http://www.rev-ed.co.uk/docs/picaxe_manual1.pdf

to learn more.